The WBH Rapid-Build Bridge Solution:

THE ESSENCE OF DESIGN

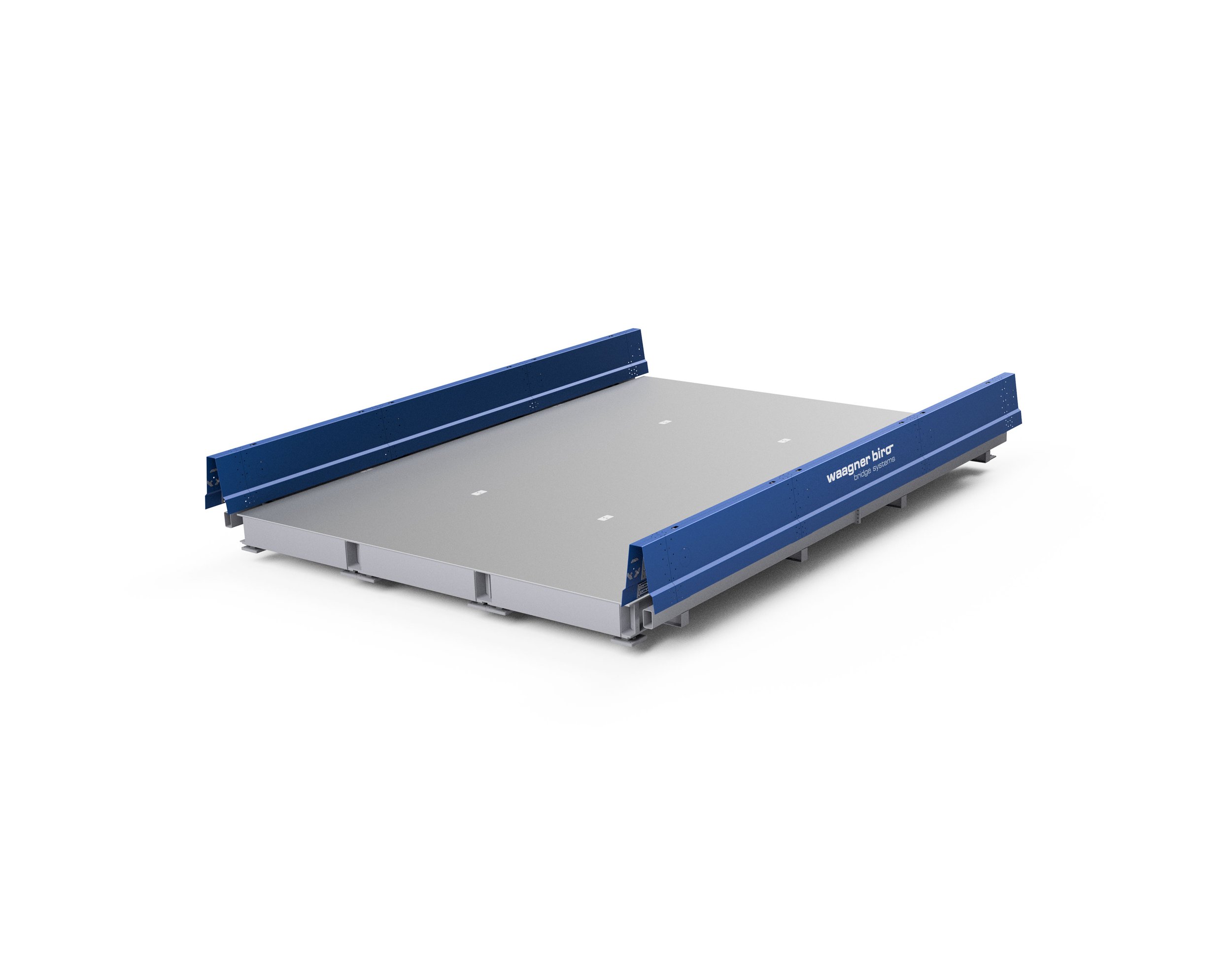

The Waagner-Biro Beam Bridge Hercules WBH is a modular construction with few individual components. It was developed for heavy loads traffic and single spans of up to 21 metres. The WBH beam bridge is suitable for temporary or semi-permanent applications, for public transportation or construction works. Available for hire or sale. Being delivered preassembled, this bridge is rapidly deployable and easily installed by crane.

Specifications for the Waagner-Biro Beam Bridge HERCULES

Type of construction: The WBH consists of prefabricated modules which are interconnected transversely to achieve single, double or multiple lane configurations.

Standard module lengths: Standard units available in the lengths of 7.5m, 10.5m, 13.5m, 16.5m and 21.0m.

Standard module width: 2.5m.

Maximum clear span: 21.0m

Multi-span bridges: Multiple spans are designed as continuous girders on intermediate supports.

Load standard: Designed for high traffic loads such as Eurocode.

Existing bridges: Can be installed on existing bridges with insufficient load capacity.

Bridge deck and deck surface: Closed steel deck with orthotropic steel deck plate. Factory applied anti-slip surface made of epoxy resin with grit. All beam bridge modules are provided with lifting lugs.

Guard rails and parapets: Guard rails comply with various restraint classes according to EN 1317. End pieces allow the transition to a landside guard rail. Stable curb elements on both sides of the carriageway.

Walkway (outside the clearance gauge): Cantilevered construction; bolted to the guardrail construction by means of head plates.

Walkway widths: 1.0 to 2.0 m.

Railing height: up to 1.3 m.

Bearings: Fixed and sliding bearings made of steel.

Manufacturing: Execution according to EN 1090-2 EXC 3.

Bolted connections: Beam bridge elements are bolted together by means of butt strap joints and pre-stressed high-strength bolted connections (HV).

Corrosion protection: Galvanised finish and/or protected with three layers of coating on top of one another, all in accordance with current standards (C5 corrosion protection class - highest protection class).

Assembly: Modules fitted with integrated lifting lugs for simple installation by crane. Bridge modules are preassembled at the factory and delivered directly to the site on flatbed trucks.